- Series: CBB81

- Tolerance: ±5% (J) ±10% (K)

- Size: 25.0*15.5*9.0*0.8mm

- Application field: General

- Packing: Through hole

CBB polypropylene film capacitor CBB81 2KV102J for sale

Description

CBB polypropylene film capacitor CBB81 2KV102J for sale

CBB polypropylene film capacitor CBB81 has high capacitance and loss factor compared with temperature charging and frequency, and has high stability. It is widely used in high frequency and pulse circuits.

CBB polypropylene film capacitor CBB81 2KV102J for sale

| ltem | Characteristics |

|---|---|

| Reference standard | GB 10190 |

| Climatic Category | 40/85/21 |

| Rated Voltage | 2000V |

| Capacitance | 0.001UF |

| Capacitance Tolerance | ±5%(J) ;±10%(K) |

| Voltage proof | 2.0UR (2S) |

| Dissipation Factor | ≤0.001 (20°C, 1KHz) |

| Insulation Resistance

≥25000MΩ |

20°C,1min |

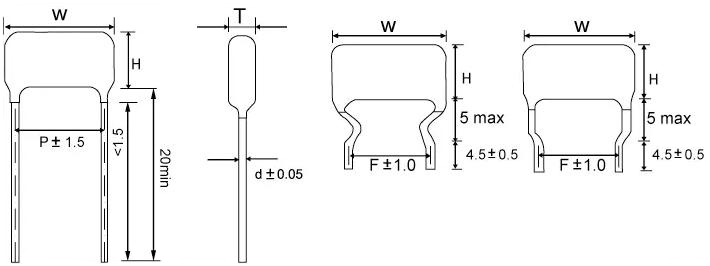

Size of CBB81 Film Capacitor

CBB81 102J 2000V Film Capacitor

W: 25.0mm

H: 15.5mm

T: 9.0mm

P±1: 18.5mm

Applications

FAQ

Q:Film capacitors have been wave soldered, lead-free soldered, about 200 degrees? High temperature can easily damage the capacitor or affect the life. Don’t know how this industry is controlled and handled? Is manual welding required? Is there a temperature limit in the capacitor specifications? Is the solder joint temperature or body temperature when labeling?

A:Hello, the temperature of the wave soldering peak of the film capacitor can be 275 ° C, which is also the temperature of the IEC standard, and the tin immersion time is 3S-5S. The other is the preheating temperature and time. Film capacitors can withstand this temperature. Does not affect electrical characteristics. The solderability temperature and soldering heat resistance temperature are stated in the specification approval book. The former is aimed at the solderability of capacitor pins, while the latter is about the influence of welding temperature on the characteristics of film capacitors.

Q: How to judge the quality of the film capacitor?

A: 1) Use a multimeter to test the resistance of the thin-film electricity. The two feet should be very high resistance. If there is a capacitance meter, measure whether the capacitance value matches the mark on the case.

2) Test performance at room temperature, including capacity, loss, insulation resistance, withstand voltage, ESR, etc.

3) Do simulated life test.

Contact Us

Email: filmcap@xuanxcapaciors.com

Ph/(whatsapp): +86-18825879082

Skype: Coco.PSH

Website: xuanxcapacitors.com