The main parameters of the capacitor include capacitance, rated voltage, loss factor, leakage current, and maximum operating temperature. These parameters are required in aluminum electrolytic capacitor data. In addition, aluminum electrolytic capacitors have parameters that are different from other capacitors.

In addition to the maximum operating temperature, the number of service life hours must be stated. Because the 1000h/105℃ aluminum electrolytic capacitor below 85C has no longer life than the 4000h/85℃ aluminum electrolytic capacitor.

1. Data analysis of general-purpose aluminum electrolytic capacitors

The main purpose of general-purpose aluminum electrolytic capacitors is for general electronic circuits, that is, general purposes, such as bypass, coupling (DC blocking), rectification and filtering, etc.

In bypass and coupling (DC blocking) applications, capacitors usually do not flow large currents. Therefore, the usual concept is that it is sufficient for general-purpose aluminum electrolytic capacitors to provide rated voltage, capacitance, loss factor, operating temperature and storage temperature range, and overall dimensions, or even only rated voltage and capacitance are required. Under this concept, this is the information given in the product samples or data sheets of most domestic aluminum electrolytic capacitors, and this is also the case for most aluminum electrolytic capacitors in Japan. In addition to the above data, famous European and American aluminum electrolytic capacitor manufacturers (such as RI-FA, EPCOS, CDE, etc.), which are famous for their rigor, also provide impedance frequency characteristic curves of capacitors at different temperatures.

In general rectifier and filter applications, users often ignore the ripple current flowing through the rectifier and filter capacitors, which often leads to early failure of electronic circuits due to early failure of aluminum electrolytic capacitors. This kind of early failure often occurs after the user has used it for half a year or more than a year. Since the warranty period has passed, this kind of damage will bring a lot of trouble and undue economic losses to the user.

With the requirements for ripple current data of aluminum electrolytic capacitors in electronic circuit applications, most of the large aluminum electrolytic capacitor manufacturers in China and most general-purpose aluminum electrolytic capacitors also provide ripple current data. This allows aluminum electrolytic capacitors to have ripple current tolerance data in rectification and filtering applications. Through these data, the expected life of aluminum electrolytic capacitors can be evaluated.

Whether it is a general-purpose aluminum electrolytic capacitor produced in China or a general-purpose aluminum electrolytic capacitor produced by a famous foreign manufacturer, most data sheets do not include equivalent series resistance parameters and impedance frequency characteristic curves of aluminum electrolytic capacitors. The reason may be that it is not necessary to give it for general purposes, or it may be that the equivalent series resistance and equivalent series inductance of general-purpose aluminum electrolytic capacitors are too large to be given.

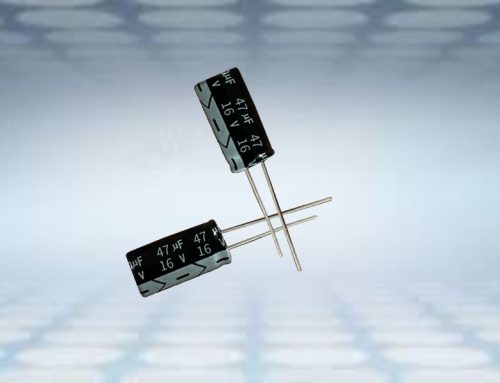

For example, the equivalent series resistance of a 100uF/16V general-purpose aluminum electrolytic capacitor may reach about 2Ω. If a ripple current of 100mA flows, a ripple voltage of 200mV will be generated. For another example, the equivalent series resistance of a 1000uF/16V general-purpose aluminum electrolytic capacitor may reach more than 0.5Ω. If a current of 1A flows, a ripple voltage of 0.5V will be generated. Such a value would be unacceptable to electronic engineers, but if this data is not given, electronic engineers may be out of sight and out of mind. Even though the performance of aluminum electrolytic capacitors is known to be poor, they are still used. If the performance cannot meet the requirements, film capacitors or ceramic capacitors with good “high frequency” performance will be connected in parallel with the aluminum electrolytic capacitors. As a result, “large capacitors” appeared It is a traditional saying that small capacitors filter low frequencies and filter high frequencies.

2. Data analysis of low ESR aluminum electrolytic capacitors

If general-purpose aluminum electrolytic capacitors are used for output rectification and filtering of switching power supplies, it will be found that general-purpose aluminum electrolytic capacitors may generate serious heat, or the filtering effect may be poor, resulting in high-amplitude peak voltages and ripple voltages. The reason is simply that the equivalent series inductance and equivalent series resistance of general-purpose aluminum capacitors are too large.

For general-purpose aluminum electrolytic capacitors around 1000uF, the resonant frequency may be 10kHz, and for general-purpose aluminum electrolytic capacitors around 100uF, the resonant frequency may be lower than 30kHz, which is not the case for rectification and filtering below 400Hz and electronic circuits with a bandwidth of 20kHz. All requirements can be met. However, aluminum electrolytic capacitors are unable to suppress or divert ripple currents of hundreds of kilohertz or even several megahertz. Aluminum electrolytic capacitors with low equivalent series resistance and low equivalent electrical inductance are required.

The biggest feature of low-ESR aluminum electrolytic capacitors is that the equivalent series resistance is significantly lower than general-purpose aluminum electrolytic capacitors, and the equivalent series inductance is also significantly reduced. In this way, under the same heat dissipation capacity, the reduction of the equivalent series power group can increase the ripple current it can withstand.

Since low ESR aluminum electrolytic capacitors are mainly used for output rectification and filtering of switching power supplies, a relatively large ripple current will flow through them. Therefore, ripple current and ESR parameters will inevitably appear in the data of low-ESR aluminum electrolytic capacitors. By understanding the ESR value of the aluminum electrolytic capacitor, we can know the filtering performance of the aluminum electrolytic capacitor.

Since the ESR of aluminum electrolytic capacitors changes with temperature, the data of low-ESR aluminum electrolytic capacitors should also include ESR conversion values at different temperatures, as well as tolerable ripple current conversion values at different temperatures and at the same frequency. In this way, we can clearly understand the impact of the parasitic parameters of the aluminum electrolytic capacitor on circuit performance under different working conditions. In addition, it is best to have impedance frequency characteristics at different temperatures and life characteristic curves under different ripple current conditions. .

Low ESR aluminum electrolytic capacitors produced in Japan and low ESR electrolytic capacitors produced in my country both provide ESR and tolerable ripple current, but they do not have impedance frequency characteristics at different temperatures and different ripple current conditions at different temperatures. life characteristic curve. Without these curves, it may not be possible to estimate the expected life of aluminum electrolytic capacitors during circuit design.

3. Data analysis of pin-type aluminum electrolytic capacitors and screw-type aluminum electrolytic capacitors

As the rated voltage and capacitance of aluminum electrolytic capacitors increase, the lead-type structure can no longer fix the aluminum electrolytic capacitors on the circuit board well, and pin-type aluminum electrolytic capacitors have emerged. Compared with lead-type aluminum electrolytic capacitors, the data of pin-type aluminum electrolytic capacitors have ESR parameters and tolerable ripple current parameters. At the same time, long-life aluminum electrolytic capacitors also appeared. If the capacitance is too large, the aluminum electrolytic capacitor will be too large. In order to fix such an aluminum electrolytic capacitor on the circuit board, there can also be a 4-pin aluminum electrolytic capacitor.

Pin-type aluminum electrolytic capacitors and bolt-type aluminum electrolytic capacitors may flow through relatively large currents, which will cause relatively large losses in the ESR of the aluminum electrolytic capacitors and generate relatively large amounts of heat. Therefore, parameters with heat dissipation capabilities are required. Therefore, pin-type aluminum electrolytic capacitors and bolt-type aluminum electrolytic capacitors from companies such as RIFA and CDE also give thermal resistance parameters under different conditions. In this way, the actual operating temperature of the electrolytic capacitor core package and shell can be deduced through the thermal group parameters and the operating conditions of the electrolytic capacitor, and then the expected life of the electrolytic capacitor can be deduced.

If there is no thermal resistance parameter, the expected life of the electrolytic capacitor can also be calculated through the relationship curve between the electrolytic capacitor’s life, ripple current, and temperature. For example, EPCOS calculates the expected life of electrolytic capacitors through the life curve of life, ripple current, and temperature.

If neither the thermal resistance of the electrolytic capacitor nor the relationship curve between the electrolytic capacitor’s life and ripple current and temperature is given, the expected life of the electrolytic capacitor cannot be calculated more accurately, and the approximate life of the electrolytic capacitor can only be roughly estimated. . This estimate will deviate greatly from the actual situation. The pin-type aluminum electrolytic capacitors and bolt-type aluminum electrolytic capacitors produced in my country and Japan do not give thermal resistance, nor do they give the relationship curve between the life of the electrolytic capacitor and the ripple current and temperature. Under different temperature conditions and different frequency conditions, the ripple current values that aluminum electrolytic capacitors can withstand are different. The temperature conversion coefficient and frequency conversion coefficient can be used to calculate the ripple current that aluminum electrolytic capacitors can withstand under actual application conditions. It is related to the multiple of the rated ripple current, and then the expected life of the aluminum electrolytic capacitor can be calculated. In order to more intuitively know the ripple current that can be tolerated at different frequencies and temperatures, RIFA also gives several acceptable ripple current values at typical temperatures and frequencies.

Relatively large power electronic circuits are directly connected to the power grid. Instantaneous overvoltage in the power grid may be added to the smoothing (filter) capacitor or DC support capacitor, causing overvoltage or even breakdown. For such applications, electrolytic capacitors need to be able to withstand instantaneous overvoltage without damage. Most aluminum electrolytic capacitors do not have instantaneous overvoltage data, but only surge voltage values. Some models of RIFA’s aluminum electrolytic capacitors provide instantaneous overvoltage parameters, so that you can avoid selecting an excessively high rated voltage and reduce the cost of use. Judging from the instantaneous overvoltage data of RIFA’s aluminum electrolytic capacitors, this model of RIFA’s aluminum electrolytic capacitors can withstand 1.5 times or even higher instantaneous overvoltage impacts. The lower the capacitance, the higher the instantaneous overvoltage it can withstand.

4. High temperature aluminum electrolytic capacitor data analysis

The working environment of electronic rectifiers and energy-saving lamps is extremely harsh, and the temperature may be as high as 105°C or even higher. At the same time, they are also required to have a long life in a high-temperature environment. It is definitely not possible to use 105℃/1000h products for such applications.

The biggest feature of high-temperature aluminum electrolytic capacitors is that they can not only work in high-temperature environments, but also have a long service life. EPCOS’s B43697 aluminum electrolytic capacitor has a service life of 3000 hours at rated voltage and 105°C ambient temperature.

Under the same temperature environment, the service life of high-voltage aluminum electrolytic capacitors is different under rated voltage, derated voltage, and overvoltage working conditions. For example, EPCOS’s B43697 aluminum electrolytic capacitor has a service life of 3000h at 105°C and 450V rated voltage, while the operating voltage drops by 420V (93% of rated voltage) is 11,500h; B43698 aluminum electrolytic capacitor has a service life of 105°C and 450V rated voltage. The service life is 10 000h, and the working voltage is 2000h when the operating voltage rises to 500V (111% rated voltage). This shows that reducing the operating voltage is beneficial to the service life of aluminum electrolytic capacitors, especially in high temperature environments. CDE data also support this conclusion

The ambient temperature in the car engine compartment is higher and may exceed 105°C, requiring a maximum operating temperature higher than 125°C or even 140°C or 150°C high-temperature electrolytic capacitors. RIFA’s PEG225 series 150℃/2000h high temperature aluminum electrolytic capacitors are specially designed for extremely high temperature working environments. Not only that, this series of aluminum electrolytic capacitors can also withstand very high ripple currents

In the data of large aluminum electrolytic capacitors, it should be noted that the ripple current that can be tolerated at different temperatures is different. For example, the ripple current that an aluminum electrolytic capacitor with a maximum operating temperature of 85°C can withstand at 40°C is 85°C. The ripple current that a 105°C aluminum electrolytic capacitor can withstand at 105°C is much lower than the ripple current of an aluminum electrolytic capacitor with a rated temperature of 85°C at 85°C. Therefore, it is wrong to only look at the ripple current that two specifications of aluminum electrolytic capacitors can withstand at their respective rated temperatures. In fact, the ripple current that a 105°C aluminum electrolytic capacitor can withstand at 85°C is greater than an aluminum electrolytic capacitor with a rated temperature of 85°C.