1.the Development of Capacitor Aluminum foil Processing Technology

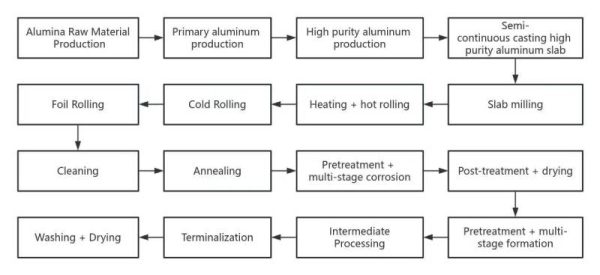

Capacitor aluminum foil processing-Aluminum electrolytic capacitors are the main varieties of capacitor products. It is estimated that the output value of aluminum electrolytic capacitors accounts for about 50% of the output value of all types of capacitors. With the development of aluminum electrolytic capacitor production, the domestic demand for electrolytic capacitor aluminum foil has also grown rapidly. However, for a long period of time in the past, due to the backwardness of domestic technology and equipment, the aluminum foil used in domestic aluminum electrolytic capacitors mainly relied on imports. After 20 years of unremitting efforts by relevant domestic enterprises and scientific research departments, this situation has been greatly improved. At present, the annual domestic demand for light foil used to manufacture aluminum electrolytic capacitors is in the range of 10,000 to 20,000 tons, but many high-performance foils still rely on imports. Reviewing the process of domestic electrolytic capacitor aluminum foil production and technological development is conducive to promoting related industries to broaden development ideas, adjust production structures, and promote the upgrading of production technology. It is also conducive to completely changing the unfavorable situation of domestic electrolytic capacitor aluminum foil products relying on imported technology.

1.1 Capacitor Aluminum foil Processing – initial Development Stage

Before the 1980s, domestic electrolytic capacitor aluminum foil was mostly produced by manual chemical corrosion, and the requirements for aluminum foil processing quality were not high. The aluminum purity used at that time was low, and the aluminum content was generally less than 99.7%. The aluminum ingots produced by many electrolytic aluminum plants could still meet the demand. At the same time, people only produced electrolytic capacitor light foil according to the production method of conventional packaging aluminum foil. The thickness of electrolytic capacitor aluminum is very thin, most of which is less than 0.1mm; in order to improve production efficiency and reduce costs, aluminum processing companies usually use continuous casting and rolling slabs and cold rolling process to organize light foil production, which omits the hot rolling processing link.

After the 1980s, China began to introduce a large number of linked electrochemical corrosion and formation production lines (Figures 1.10 and 1.11). The requirements of aluminum electrolytic capacitor manufacturers for formation specific capacitance have been continuously improved, prompting continuous improvement of aluminum foil corrosion and formation processes. At the same time, the requirements for the purity of aluminum foil in corrosion processing are getting higher and higher, and the requirements for the processing quality of aluminum foil are getting more and more precise. However, at that time, the domestic production of electrolytic capacitor light foil did not update the production concept in time, and the original production technology was still adopted. Continuous cast and rolled plates do not undergo hot rolling processing, which largely loses the space to adjust the internal organizational structure; and continuous casting and rolling also makes it difficult to accurately control the purity and organizational structure of the rolled plate surface, which cannot meet the needs of subsequent processing. Therefore, corrosion processing and chemical processing companies have to turn to importing foreign light foil to meet the requirements of the increasing specific capacitance of chemical foil. By the end of the 1980s, with the continuous increase in the import volume of electrolytic capacitor light foil, the production and sales volume of domestic light foil fell sharply.

In order to produce light foil that meets the requirements of corrosion and chemical formation, in addition to strictly controlling the external dimensions and processing quality of the light foil, industrial production must also have strict requirements on its internal organizational structure; at the same time, it is also necessary to use high-purity aluminum and strictly control the content and distribution of various trace elements in the aluminum foil. At that time, people did not realize the important role of the internal organizational structure of aluminum foil in the technical quality of electrolytic capacitor aluminum foil; there was no domestic production enterprise that could stably provide high-purity aluminum ingots. Most people in the industry only realized that domestic aluminum processing equipment was not suitable for the production of electrolytic capacitor light foil. However, the cost of introducing processing equipment was very high at that time, and general aluminum processing enterprises could not afford it. Therefore, the update of related production technology stagnated, and some aluminum processing enterprises were even forced to close.

After entering the 1990s, when domestic light mainly relied on imports, the price of imported light rose rapidly, such as the price of high-voltage anode aluminum foil rose to more than 130,000 yuan/t. On the one hand, domestic light foil cannot make the product performance of chemical foil meet market demand; on the other hand, the price of imported light foil makes the produced chemical foil unable to generate profits. This situation has put most domestic corrosion and chemical processing enterprises in a very difficult situation; the domestic aluminum electrolytic capacitor industry as a whole faces severe tests.

1.2 Capacitor Aluminum Foil Processing-Rapid Development Stage

In the late 1980s, Xinjiang Zhonghe Company (formerly Urumqi Aluminum Plant) successfully realized the process technology of mass production of high-purity aluminum by three-layer electrolyte method, and soon formed an annual production capacity of 5,000 tons of high-purity aluminum ingots, becoming the largest high-purity aluminum production enterprise in China, with an output accounting for more than 80% of the total domestic output at that time. The purity of its aluminum ingots reached a level of more than 99.994%, laying a raw material foundation for the large-scale production of high-quality electrolytic capacitor aluminum foil in China.

In 1993, the former State Economic and Trade Commission approved the project in the second batch of industry-university-research projects and funded Xinjiang Zhonghe Company to carry out research and development of high-voltage and low-voltage anode aluminum foil production technology. In 1994, Xinjiang Zhonghe Company made a breakthrough in development research and formed its own patented technology. The technical indicators of its high-voltage anode aluminum have reached international standards, and the intrinsic quality of low-voltage anode aluminum foil has gradually reached market requirements. In 1996, Xinjiang Zhonghe Company took advantage of its own raw material advantages and invested in the construction of the first production line in China that uses hot rolling and cold rolling processes to specialize in the production of electrolytic capacitor foil. From 1996 to 2001, Xinjiang Zhonghe Company mainly produced low-voltage anode foil, which accounted for 70% of the anode aluminum foil market share. The output increased year by year and became the main supplier of domestic anode foil at that time. When Xinjiang Zhonghe Company’s products were about to be put on the market, the price of imported light boxes immediately dropped sharply. For example, the price of high-voltage anode aluminum foil quickly dropped to 80,000 to 90,000 yuan/t, which greatly alleviated the difficulties of many domestic corrosion and chemical processing companies.

In 2000, the Beijing Municipal Science and Technology Commission established a science and technology project to fund Beijing Weihao Company to carry out research and development of high-voltage anode aluminum foil production technology. At the beginning of 2001, Beijing Weihao Company quickly made a breakthrough on the basis of the previous high-voltage anode aluminum technology development. After identification, the intrinsic technical quality of its high-voltage anode aluminum foil reached international standards. Beijing Weihao Company produced more than 1,100 tons of high-quality high-voltage anode aluminum foil that year, and immediately became the company with the largest sales volume of high-voltage anode aluminum foil in China, and was welcomed by corrosion and chemical processing companies.

Since the above two aluminum processing companies use traditional domestic processing equipment to produce aluminum, the equipment depreciation cost is very low. Therefore, under the condition of obtaining higher profits, the selling price of their products is only in the range of 40,000 to 50,000 yuan/t. This has caused the price of imported high-voltage anode aluminum foil to fall to the level of 40,000 to 50,000 yuan/t.

As a backbone enterprise in the domestic aluminum processing industry, Southwest Aluminum Company has been engaged in the production and technology development of electrolytic capacitor aluminum foil for many years. In 2001, the State Economic and Trade Commission issued a scientific research task to Southwest Aluminum Company to develop the production process and technology of electrolytic capacitor high-voltage anode aluminum foil. Southwest Aluminum Company quickly achieved success by taking advantage of its equipment and technology on the basis of the original aluminum foil varieties. The inherent technical quality of the products developed has also reached international standards and is welcomed in the market.

Since the 1990s, private enterprises engaged in electrolytic capacitor aluminum corrosion and chemical processing have sprung up like mushrooms after rain, and gradually become the main body of the corrosion and chemical industry. These enterprises have carried out relatively independent research and development of corrosion technology and chemical formation technology. Some enterprises have also cooperated with domestic scientific research institutions to make great improvements in related technologies. Fierce market competition has also prompted the emergence of new corrosion and chemical formation processes. In 1994, Xi’an Jiaotong University developed a corrosion technology of adding dichromate to the corrosion solution based on the characteristics of the domestic optical surface state and obtained a patent, which significantly improved the specific capacitance of aluminum foil. In 2003, Beijing University of Science and Technology successfully developed a new copper removal process in the corrosion process of domestic cathode aluminum foil. Without losing specific capacitance, the surface electrochemical technology quality of cathode aluminum foil reached international standards. Due to the efforts of domestic production enterprises and scientific research institutions, the production of domestic electrolytic capacitor aluminum foil subsequently formed a certain overall strength, and the related industry came out of the trough and developed rapidly.

1.3 New Challenges

However, while the production of electrolytic capacitor aluminum foil in my country is developing rapidly, related technologies in the world are also constantly being updated. Overall, the level of domestic brands is still lagging behind the international advanced level. The internationally advanced electrolytic capacitor aluminum foil production technology is outstanding in that it can accurately control the surface state and internal structure of the light foil according to the needs of corrosion and formation, can produce high-purity aluminum ingots by low-energy segregation method, can produce large-size and weight specifications of aluminum foil rolls, and thus significantly improve production efficiency and improve product quality stability. High uniformity corrosion pore technology and high specific capacitance corrosion and formation technology have been developed. In recent years, the international community has paid more and more attention to the environmental protection issues of electrolytic capacitor aluminum foil production, and even legislated to regulate the behavior of related industries. With the change of international trends, my country’s electrolytic capacitor aluminum industry will inevitably face many new challenges.

Japan’s aluminum electrolytic capacitor and corrosion and chemical foil production has undergone a process of reorganization and elimination. Eventually, hundreds of manufacturers were integrated into less than 10 large enterprises with strong competitiveness, forming a relatively economical and reasonable industrial structure. At present, the production of domestic electrolytic capacitors is mainly undertaken by four or five companies with certain strength. However, with the market-oriented development of the domestic economy, dozens of private enterprises have emerged in the corrosion and chemical fields; there are hundreds of aluminum electrolytic capacitor manufacturing companies, forming a relatively scattered production pattern. Fierce market competition has made the technology of corrosion and chemical companies quite closed, mainly based on their own isolated research and development, lacking an atmosphere of cooperation, communication, and common improvement. The large number of companies, scattered operations, and insufficient market standardization make it difficult for inferior and low-priced products to find a living space and be eliminated. This not only hinders the breakthroughs of various companies in high-tech, but also affects the improvement of the overall level of the industry. Dozens of corrosion and chemical companies will put forward very different, possibly reasonable or unreasonable requirements for light foil products based on their relatively independent technical systems. This situation is also likely to cause light companies to disperse their energy and lose their direction in technological updates and transformations. The above-mentioned dispersion and relative closedness of corrosion processing also cause the unreasonableness, diversity and uncertainty of product technical quality requirements. In actual production, it is often the case that the same light foil has good performance after corrosion by one enterprise, but very poor performance after corrosion by another enterprise. The incoordination of the connection between the various production links, coupled with the different commercial interests between enterprises, often complicates technical problems due to non-technical factors, and cannot be solved in a timely and reasonable manner.

Some domestic production enterprises only undertake a part of the high-purity aluminum production, light production, corrosion processing, and chemical processing of electrolytic capacitor aluminum foil. For example: light foil production enterprises do not perform corrosion, chemical production corrosion, and chemical formation enterprises do not understand the production process of light foil; the technical and product development personnel of the enterprise are often only familiar with the production links involved. In fact, the technical quality of electrolytic capacitor aluminum foil is closely related to all links of high-purity aluminum production and light foil, corrosion, and chemical processing. Therefore, there is a certain actual contradiction between the current status of the enterprise’s technical strength and the technical requirements of electrolytic capacitor aluminum foil. The basic theoretical knowledge involved in the production of electrolytic capacitor aluminum foil includes multiple disciplines such as light metal metallurgy, metallurgy, and metal corrosion. At present, domestic professional researchers have not been able to break through the boundaries of these three disciplines. Even in enterprises involved in all production links, relevant technical and product developers often cannot fully understand and systematically master the technical points of all disciplines in the production process of electrolytic capacitor aluminum foil. This phenomenon also hinders the rapid improvement of the technical quality of domestic aluminum foil. It can be seen that the technical and product developers of enterprises and researchers of scientific research units need to break through the boundaries of the original technical fields and disciplines, broaden the knowledge and technical scope involved, and comprehensively learn and master the relevant theoretical knowledge to lay a good foundation for the deep and sustainable development of the electrolytic capacitor aluminum foil industry.

Based on the current situation, many domestic technicians engaged in the production of electrolytic capacitor aluminum foil still maintain the basic technical background and knowledge structure of processing traditional structural aluminum materials, and organize production and management based on this. However, electrolytic capacitor aluminum foil is a functional material. It not only has more stringent and complex requirements on internal organizational structure and external processing quality, but also its internal organizational structure and external processing quality are closely related to its corrosion formation behavior and ultimately capacitance parameters and winding performance. At the same time, most of the production equipment used by domestic related enterprises are relatively simple ordinary equipment, which cannot meet the many special requirements required for the production of electrolytic capacitor aluminum foil. This contradiction between knowledge structure and production equipment and electrolytic capacitor aluminum foil product requirements is often reflected in the low level of product technical parameters, unstable quality, poor market adaptability and other aspects. Therefore, improving and adjusting this contradiction is also one of the keys to improving the technical quality of domestic light foil and narrowing the gap with foreign products. At the same time, the technical development department must also deeply and meticulously study the relevant basic scientific issues, strive to break the situation of continuous import and imitation of foreign technology, and develop new electrolytic capacitor aluminum foil technologies with independent intellectual property rights, so that my country’s electrolytic capacitor aluminum foil industry can truly go global.

Studies have shown that lead ions have a significantly higher standard electrode potential than aluminum ions. Trace amounts of lead in aluminum foil will be enriched on the surface and will promote corrosion and pore formation on the surface of aluminum foil, which is conducive to helping overcome the above-mentioned shortcomings of domestic light foil. At the same time, dichromate corrosion technology is also conducive to overcoming the surface quality defects of domestic light foil caused by the use of ordinary processing equipment. Therefore, many domestic companies have adopted the dichromate corrosion technology banned in Europe and produced lead-containing light foil that is gradually being eliminated abroad. It is well known that lead and dichromate containing hexavalent chromium are toxic carcinogens. Excessive lead absorption by the human body can lead to neurological diseases, and ingestion of dichromate can lead to acute renal damage and multiple organ failure, and even death. In the process of manufacturing aluminum foil for electrolytic capacitors, various measures can be taken to avoid the harm of lead and hexavalent chromium to operators. If strict environmental protection measures are taken, the discharge and treatment of industrial waste liquids or waste containing lead and hexavalent chromium can also be solved. However, when capacitors containing residual lead and hexavalent chromium are installed in electronic products and are scrapped after consumption in the market, the residual lead and hexavalent chromium will have an important impact on the disposal of the electronic products.

In January 2003, the European Parliament and the European Council adopted the “Directive on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment”. The directive stipulates that member states will ensure that new electronic and electrical equipment placed on the market from July 1, 2006 does not contain lead, mercury, cadmium, hexavalent chromium, polybrominated diphenyl ethers or polybrominated biphenyls. This EU directive will affect the EU market, which accounts for 25% of my country’s home appliance exports. Under such an environmental situation, the Japanese electronics industry has acted very quickly. For example, Sony announced that all its electronic products will be lead-free in March 2005. Some domestic companies have also begun to develop non-chromate corrosion technology for domestic light foil. The “Electronic Information Product Pollution Prevention and Control Management Measures” issued by the Ministry of Information Industry also stipulates: “Measures should be taken to gradually reduce and eliminate the content of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl (PBB), polybrominated diphenyl ether (PBDE) and other toxic and harmful substances in electronic information products.” It can be seen that the transformation of domestic electrolytic capacitor aluminum foil to lead-free and hexavalent chromium-free is imperative. Otherwise, the production and export of domestic electrical products will suffer a heavy blow due to the problems of aluminum electrolytic capacitor components.

After years of efforts by relevant production enterprises and research institutions, my country’s electrolytic capacitor aluminum industry has gotten rid of the trough and embarked on a path of rapid development. It has considerable strength in production technology and scientific research and development. At present, my country can use ordinary domestic equipment to produce electrolytic capacitor aluminum foil with the same quality as some imported products, and has obvious competitive advantages in price. Today, my country can be called a major producer of aluminum electrolytic capacitors, but it is not a strong country, because my country as a whole still has a significant gap with the world’s advanced level. In the future, the electrolytic capacitor aluminum foil industry should pay special attention to adapting to changes in the international situation, striving to adjust its own industrial structure, actively developing and updating production technology, and paying special attention to the development of environmental protection technology to ensure the industry’s lasting international competitiveness. At present, many provinces and regions in China have invested in the construction of new production lines for electrolytic capacitor light foil, corrosion foil, and chemical foil on a large scale. I believe that after several years of joint research, exploration and development by all parties, the domestic electrolytic capacitor aluminum foil industry will surely achieve greater development.

Summary:

This article mainly talks about the initial development stage and rapid development stage of capacitor aluminum foil processing technology and how to actively develop and update production technology in the future, especially paying attention to the development of environmental protection technology to ensure the industry’s lasting international competitiveness. For more information about capacitors, please click:https://capacitorsfilm.com