1.1 Detection method of common capacitor

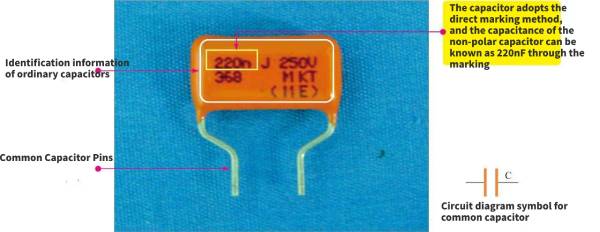

When testing ordinary capacitors, you can first read the nominal capacitance of the ordinary capacitor to be tested according to the identification information of the ordinary capacitor, then use a multimeter to detect the actual capacitance of the ordinary capacitor to be tested, and finally compare the actual measured value with the nominal value, So as to distinguish the quality of ordinary capacitors.

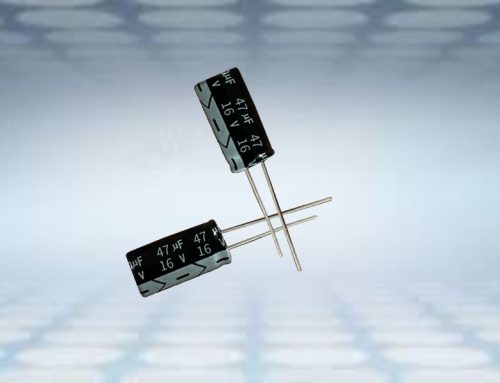

Figure 3-33 Physical appearance of a common capacitor to be tested

1.1.1 Roughly measure the capacitance of a capacitor

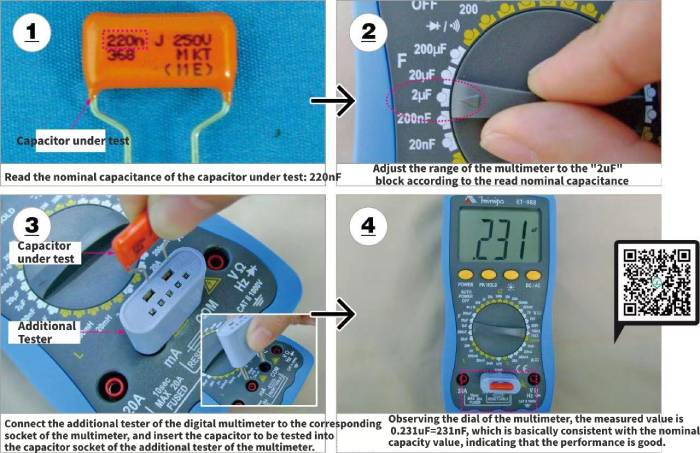

When roughly detecting the capacitance of ordinary capacitors, generally choose a digital multimeter with capacitance measurement function, and cooperate with its additional tester to complete the detection of capacitor capacitance.

Figure 3-34 Use an additional tester to check the capacitance of a common capacitor

Under normal circumstances, when a multimeter is used to detect a capacitor, it should have a fixed capacitance and be close to the nominal value. If the measured capacitance differs greatly from the nominal value, it means that the measured capacitor is damaged.

In addition, it should be noted that when using a multimeter to detect the capacitance of a capacitor, the capacitance of the measured capacitor should not exceed the range of the multimeter, otherwise the measurement result will be inaccurate and it will not be possible to judge whether it is good or bad.

When detecting ordinary capacitors (non-polar), different detection methods can be adopted according to the capacitance range of the capacitor.

◇ Detection of capacitors with capacitance less than 10pF

The capacitance of this type of capacitor is too small, and when tested with a multimeter, it can only roughly detect whether there is leakage, internal short circuit or breakdown. When testing, the “×10k” ohm block of the multimeter can be used to detect the resistance value, which should be infinite under normal circumstances. If the detection resistance is zero, it means that the measured capacitor is damaged by leakage or internal breakdown.

◇ Detection of capacitors with a capacitance of 10pF~0.01μF

This type of capacitor can be used to detect charging and discharging phenomena on the basis of connecting transistor amplification components, that is, to amplify the charging and discharging process of the capacitor, and then use the “×1k” ohm block of the multimeter to detect. Under normal circumstances, the pointer of the multimeter should have Obvious swings indicate that the charging and discharging performance is normal.

◇ Detection of capacitors with capacitance above 0.01μF

When detecting this type of capacitor, you can directly use the “×10k” ohm block of the multimeter to detect whether the capacitor has a charging and discharging process, and whether there is a short circuit or leakage inside.

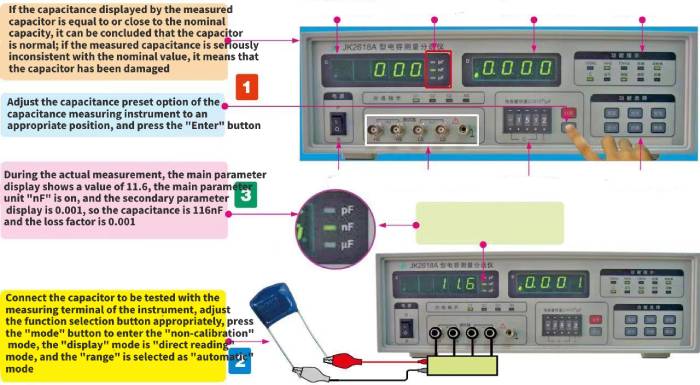

1.1.2 Accurate measurement of capacitor capacitance

If you need to accurately measure the capacitance of the capacitor (the multimeter can only measure roughly), you need to use a dedicated “inductance/capacitance measuring instrument”, as shown in Figure 3-35.

Figure 3-35 Use a special measuring instrument to test the capacitance of an ordinary capacitor

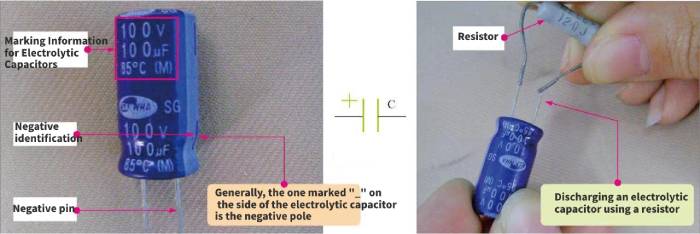

1.2 Detection method of electrolytic capacitor

There are two ways to detect whether the electrolytic capacitor is normal: one is the detection of capacitance; the other is the detection of DC resistance (that is, to detect the state of charging and discharging).

1.2.1 Detection method of capacitance of electrolytic capacitor

Before the test, first identify the polarity of the pins of the electrolytic capacitor to be tested, and then use a resistor to discharge the electrolytic capacitor to avoid the residual charge in the electrolytic capacitor from affecting the test result, as shown in Figure 3-36.

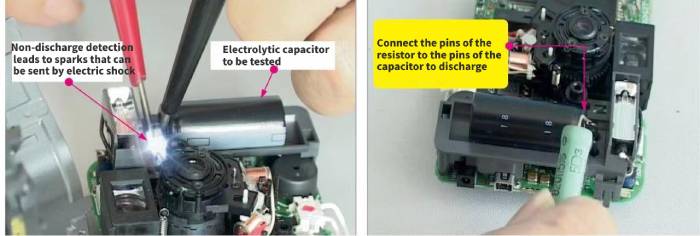

Figure 3-36 Discharge operation of the electrolytic capacitor under test

The discharge operation of electrolytic capacitors is mainly for capacity electrolytic capacitors. Since the large-capacity electrolytic capacitor may have a lot of charge during work, such as a short circuit, it will generate a strong current and cause an electric shock accident, as shown in Figure 3-37, which is easy to damage the multimeter, and it should be tested with a resistor first. . Generally, a resistor with a small resistance value can be selected, and the pin of the resistor can be connected to the pin of the electrolytic capacitor to discharge.

Figure 3-37 Electric shock sparks and discharge methods caused by the detection of undischarged electrolytic capacitors

Under normal circumstances, the working voltage of an electrolytic capacitor is above 200V, and it needs to be discharged even if the capacitance is relatively small. For example, a 60μF/200V capacitor belongs to a large-capacity capacitor because of its high working voltage. In practical applications, common capacitors 1000μF/50V, 60μF/400V, 300μF/50V, etc. are all large-capacity electrolytic capacitors.

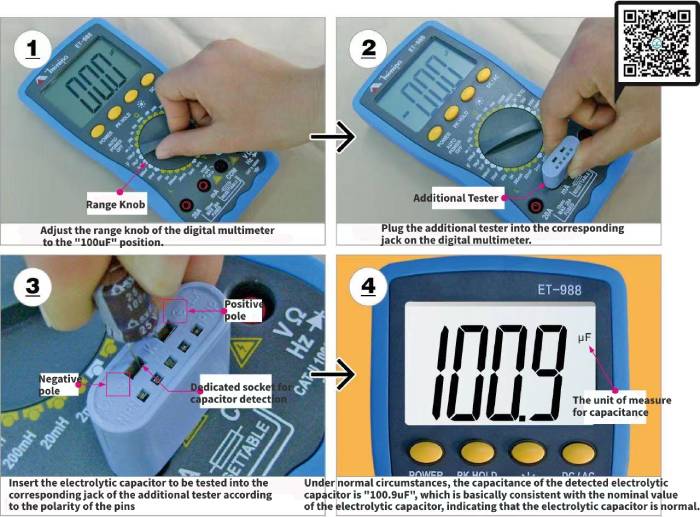

After the discharge operation is completed, use a digital multimeter to detect the capacitance of the electrolytic capacitor to judge the performance of the electrolytic capacitor to be tested, as shown in Figure 3-38.

Figure 3-38 Use a digital multimeter to detect the capacitance of an electrolytic capacitor

1.2.2 Detection method of DC resistance of electrolytic capacitor

When detecting electrolytic capacitors, in addition to using a digital multimeter to detect whether the capacitance is normal, you can also use a pointer multimeter to detect the charging and discharging process of a larger electrolytic capacitor, and judge whether the electrolytic capacitor under test is normal by detecting the charging and discharging of the electrolytic capacitor.

When testing the forward DC resistance of the electrolytic capacitor, the pointer of the pointer multimeter swings faster, so pay attention to it when testing. If the pointer of the multimeter does not swing, it means that the electrolytic capacitor has lost its capacitance.

For larger electrolytic capacitors, a multimeter can be used to detect the charging and discharging process; for smaller capacitors, it is not necessary to use this method to detect the charging and discharging process of electrolytic capacitors.

Usually, several different test results will be encountered when testing the DC resistance of electrolytic capacitors, and the cause of damage to electrolytic capacitors can be roughly judged through different test results.

According to the previous study, there is a kind of tantalum electrolytic capacitor in the electrolytic capacitor. The capacitor is patch type and installed in the circuit board. Therefore, when detecting this type of capacitor, the detection method of DC resistance cannot be used. Usually, a multimeter is used to detect its capacitance, and the detected capacitance is compared with the nominal value. To judge the performance of tantalum electrolytic capacitor itself.