What are the differences between solid capacitors and electrolytic capacitors?

Solid capacitors and electrolytic capacitors are two capacitor products that we are more familiar with. Each of these two capacitors has its own functions and advantages. Different electrical appliances choose different types of capacitors. It is necessary to understand various types of capacitors in order to meet your needs. To purchase suitable capacitor products, this article will educate you on the differences between solid capacitors and electrolytic capacitors.

The difference between solid capacitors and aluminum electrolytic capacitors

1. Different dielectric materials used

The dielectric materials used in solid capacitors and aluminum electrolytic capacitors are different. The dielectric materials used in solid capacitor are polymers with strong conductivity. They have strong stability and can achieve good use effects. The dielectric material used by the appliance is electrolyte. When the electrolyte is used for a long time, it is easy to chemically react with alumina, resulting in unstable operation of the appliance and even an explosion.

2. The usage performance displayed is different.

When used, solid capacitor show far better performance than aluminum electrolytic capacitors. They have strong high temperature resistance, are very easy to conduct electricity and can be filtered, making the frequency of electrical appliances very stable, and the electronics The component is environmentally friendly and has a very long service life due to its stable properties during use.

3. Different application fields

When used, solid capacitors are far superior to aluminum electrolytic capacitors, so they are suitable for use in some low-voltage, high-current circuits. Solid capacitor are often used in various digital products, such as computer motherboards and cameras. And some industrial computers and other products, solid capacitor are often used.

Advantages of solid capacitors and aluminum electrolytic capacitors

In terms of electrical performance, solid capacitors and ordinary electrolytic capacitors each have their own advantages. The biggest advantage of the former is that it does not use liquid electrolyte, which makes it less likely to “bulge” or “explode” when heated. It has long life, good thermal stability, and is suitable for high-frequency working environments: the latter is cheap, has large capacity, and has high voltage resistance.

Since the solid capacitor uses conductive polymer products as the dielectric material, the material will not interact with alumina and will not explode after being energized. At the same time, it is a solid product, so naturally there is no possibility of explosion due to thermal expansion. situation. Solid capacitor have excellent characteristics such as environmental protection, low impedance, high and low temperature stability, high ripple resistance and high reliability. They are currently the highest-end electrolytic capacitor products.

Since the characteristics of solid capacitors are much better than those of liquid aluminum capacitors, solid capacitors can withstand temperatures up to 350 degrees and have excellent conductivity, frequency characteristics and lifespan. They are suitable for low voltage and high current applications and are mainly used in digital products such as thin DVDs and projectors. machines and industrial computers, etc. In recent years, it has also been widely used in computer motherboard products.

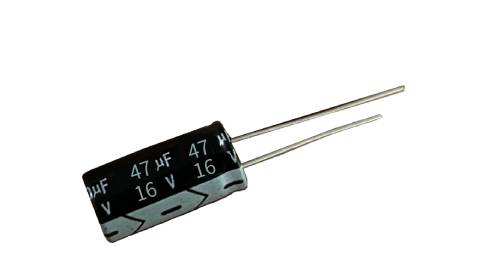

The capacity of an electrolytic capacitor is generally much larger than that of other types of capacitors. This is because it uses an electrolyte, which has a very high conductivity, which allows the capacity of the electrolytic capacitor to reach a very high value and be able to store more electrical energy.

In conclusion

In summary, there are significant differences in materials, performance, and applications between solid capacitors and electrolytic capacitors, so which type of capacitor to choose depends on specific application needs and budget. Electrolytic capacitors are suitable for low-frequency applications that require large capacities, while solid capacitor are suitable for applications in high-frequency, high-performance, and high-temperature environments.